Business

-

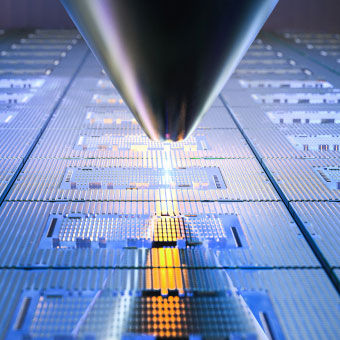

Metal Heater

Read moreIcon -

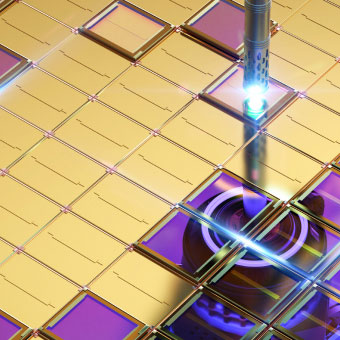

Ceramic Heater

Read moreIcon -

Electrostatic Chuck (ESC)

Read moreIcon -

Precision Processing & Welding

Read moreIcon -

Cleaning

Read moreIcon -

Special Coating

Read moreIcon -

Thermal Fluid

Read moreIcon

Welcome to TTS

We are committed to delivering customer satisfaction through superior quality and service.

We continually strive to lead the high-tech industry through constant research and development.

Directions

Please provide the location of TTS Co., Ltd.'s business site and submit your inquiry.

To inquireIcon-

Hwaseong

Address

27-6, Udeung-gil, Hyangnam-eup, Hwaseong-si, Gyeonggi-do, Republic of Korea

Tel

+82-31-366-6030

-

Cheonan

Address

56 Pungsesandan 3-ro, Pungse-myeon, Dongnam-gu, Cheonan-si, Chungcheongnam-do

Tel

+82-41-903-4383