Business Areas

Business

홈

- Business Areas

- Electrostatic Chuck (ESC)

Electrostatic Chuck (ESC)

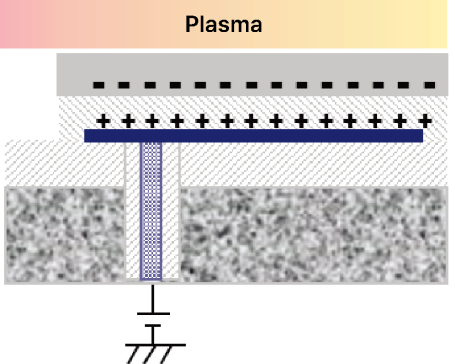

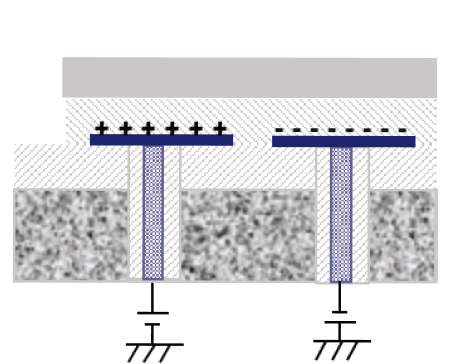

By applying an electric field between the wafer/glass surface and the electrodes in the ESC, an attractive force is exerted on the wafer/glass.

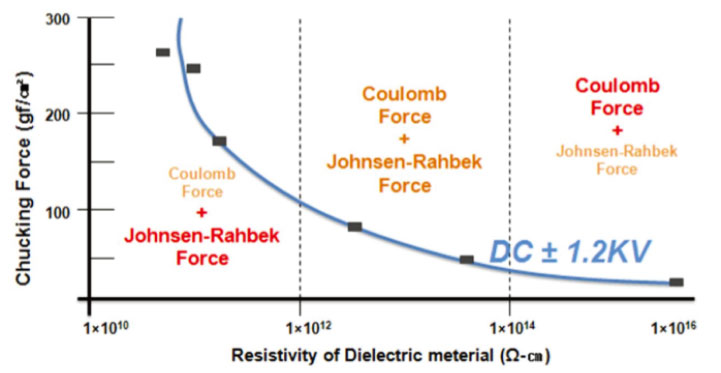

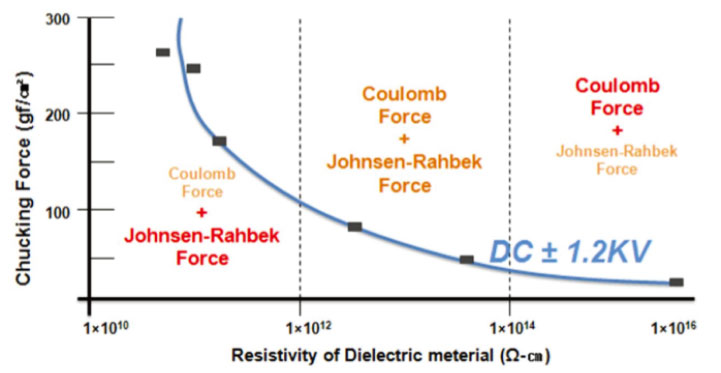

- Volumetric Resistance Control Technology (Johnson-Rahbek Model and Coulomb Force Model Available)

- Chucking and De-Chucking Time Control Technology

- Sealing Technology: Apply Al2O3 Ceramic Sealing Technology, secure withstand voltage of ~10 kV, and increase durability in corrosive environments.

-

- Unipolar (monopolar) ESC

-

F/A = ½εrεo (V/d)²

F/A = ½εrεo (V/d)²

-

- Bipolar ESC

-

F/A = 1/8εrεo (V/d)²

F/A = 1/8εrεo (V/d)²

-

- Emboss Type Unipolar

ESC for D/E Process -

- Emboss Type Unipolar

-

- Flat Type Unipolar ESC

for D/E Process -

- Flat Type Unipolar ESC

-

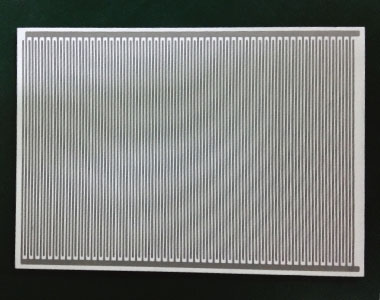

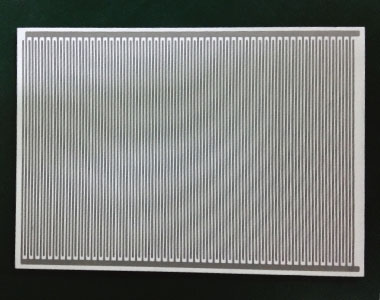

- Fine Pitch Type Bipolar ESC

for Glass Transfer -

- Fine Pitch Type Bipolar ESC

- Electrostatic Chuck (ESC)

- info

Electrostatic Chuck (ESC)

By applying an electric field between the wafer/glass surface and the electrodes in the ESC, an attractive force is exerted on the wafer/glass.

- Volumetric Resistance Control Technology (Johnson-Rahbek Model and Coulomb Force Model Available)

- Chucking and De-Chucking Time Control Technology

- Sealing Technology: Apply Al2O3 Ceramic Sealing Technology, secure withstand voltage of ~10 kV, and increase durability in corrosive environments.

-

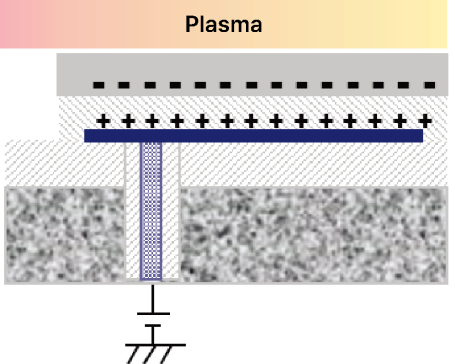

- Unipolar (monopolar) ESC

-

F/A = ½εrεo (V/d)²

F/A = ½εrεo (V/d)²

-

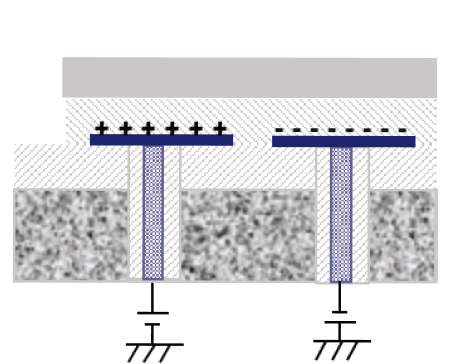

- Bipolar ESC

-

F/A = 1/8εrεo (V/d)²

F/A = 1/8εrεo (V/d)²

-

- Emboss Type Unipolar

ESC for D/E Process -

- Emboss Type Unipolar

-

- Flat Type Unipolar ESC

for D/E Process -

- Flat Type Unipolar ESC

-

- Fine Pitch Type Bipolar ESC

for Glass Transfer -

- Fine Pitch Type Bipolar ESC

- detail_img

-