Business Areas

Business

홈

- Business Areas

- Precision Processing & Welding

- Welding

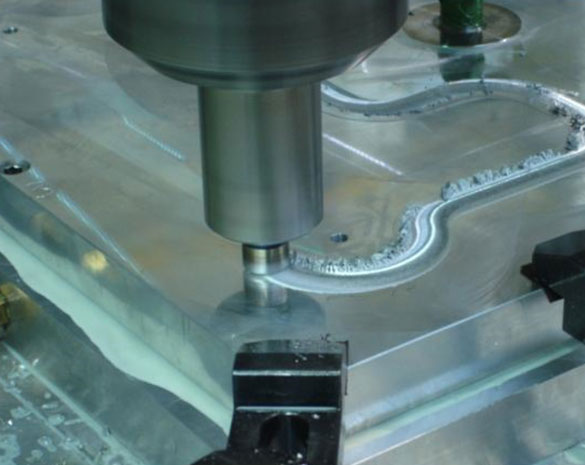

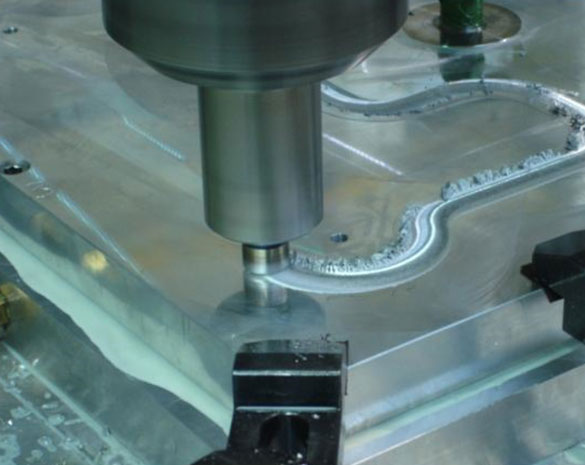

FSW welding

- Non-Fusion Solid-State Welding - Minimizing the HAZ (Heat Affected Zone) that occurs during welding

- Environmentally friendly welding technology (No ignition risk, No arc, No filler metal, No shielding gas, No fume)

-

- FSW welding

-

Special Metal Welding

- Hastelloy, Stainless Steel Metal Welding

- Welding of semiconductor special metal parts sensitive to deformation

- Cost-saving welding for ring-type structures

-

- Inner Tube Flange

-

-

- Manifold

-

-

- Rotation Flange

-

Diffusion Bonding

Application & Features

- Structures Using Multi-Layer or Multi-Gas

- Structures Difficult to Weld, Parts Sensitive to Deformation

- Improved Adhesion of Embedded Heating Wires or Fluid Lines (Tubes)

- No Residual Stress During Welding, No Change Over Time

- Solid-State Welding - Minimizes HAZ (Heat Affected Zone) During Welding

- Uniform Flatness Characteristics

- Eco-Friendly Welding Technology (No Ignition Hazard, No Arc, No Filler Material, No Protective Gas, No Fume)

- Dissimilar Metal Welding (Aluminum + Zinc, Carbon Steel + Aluminum, Gold + Silver, Titanium (Copper) + Stainless Steel)

-

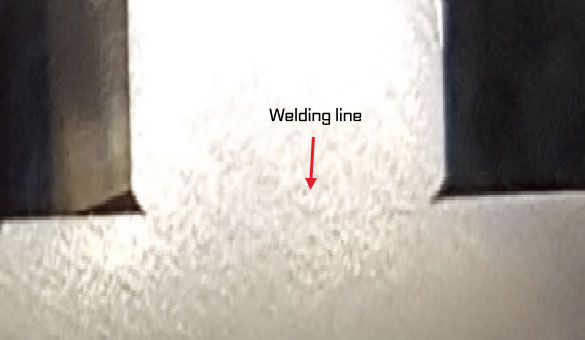

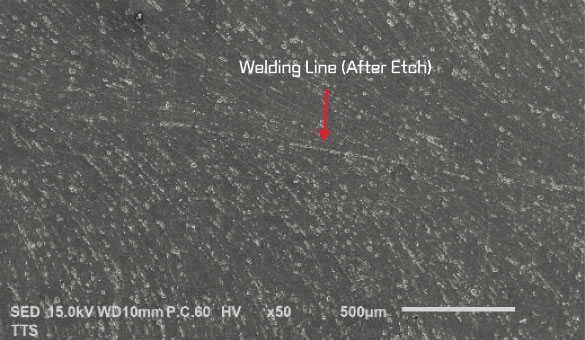

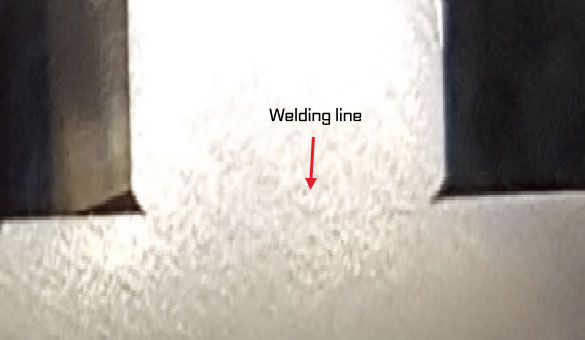

- Welded section

-

-

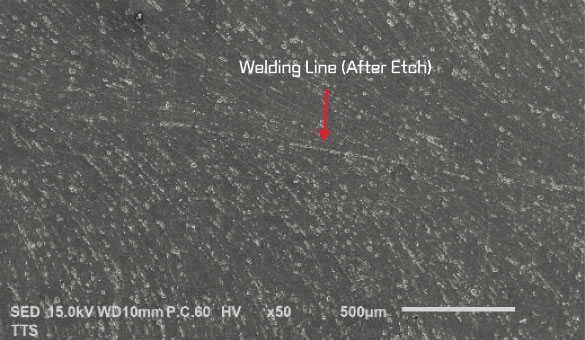

- Welded section after etching

-

※ Applied parts: Semiconductor metal heaters, quartz heaters, display susceptors, multiple gas diffusers, showerheads, etc

-

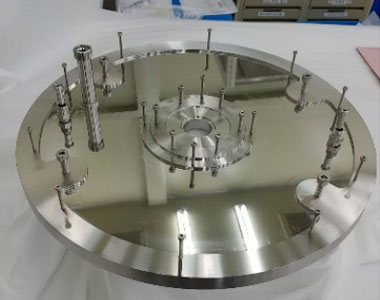

- Metal heater with Diffusion Bonding

-

- Ensuring the Adhesion of Heating Wires

- Increased Freedom in Heating Wire Design

- Minimize Deformation Due to Force

-

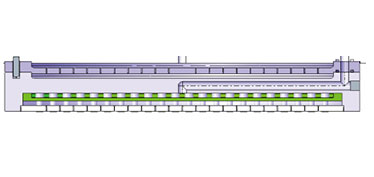

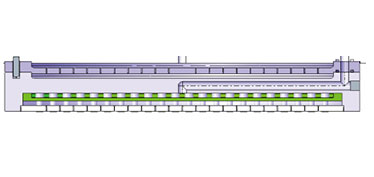

- Multiple Gas Shower Head with Diffusion Bonding

-

- Can Be Configured with a Double Flow Path

- Increased Design Freedom with Eurovech

- Can Be Joined to Different Materials

- Welding

- info

FSW welding

- Non-Fusion Solid-State Welding - Minimizing the HAZ (Heat Affected Zone) that occurs during welding

- Environmentally friendly welding technology (No ignition risk, No arc, No filler metal, No shielding gas, No fume)

-

- FSW welding

-

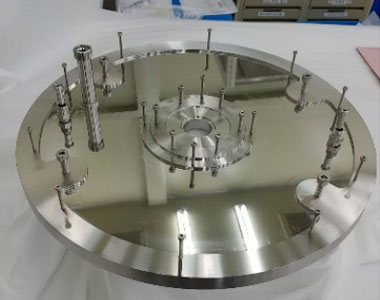

Special Metal Welding

- Hastelloy, Stainless Steel Metal Welding

- Welding of semiconductor special metal parts sensitive to deformation

- Cost-saving welding for ring-type structures

-

- Inner Tube Flange

-

-

- Manifold

-

-

- Rotation Flange

-

Diffusion Bonding

Application & Features

- Structures Using Multi-Layer or Multi-Gas

- Structures Difficult to Weld, Parts Sensitive to Deformation

- Improved Adhesion of Embedded Heating Wires or Fluid Lines (Tubes)

- No Residual Stress During Welding, No Change Over Time

- Solid-State Welding - Minimizes HAZ (Heat Affected Zone) During Welding

- Uniform Flatness Characteristics

- Eco-Friendly Welding Technology (No Ignition Hazard, No Arc, No Filler Material, No Protective Gas, No Fume)

- Dissimilar Metal Welding (Aluminum + Zinc, Carbon Steel + Aluminum, Gold + Silver, Titanium (Copper) + Stainless Steel)

-

- Welded section

-

-

- Welded section after etching

-

※ Applied parts: Semiconductor metal heaters, quartz heaters, display susceptors, multiple gas diffusers, showerheads, etc

-

- Metal heater with Diffusion Bonding

-

- Ensuring the Adhesion of Heating Wires

- Increased Freedom in Heating Wire Design

- Minimize Deformation Due to Force

-

- Multiple Gas Shower Head with Diffusion Bonding

-

- Can Be Configured with a Double Flow Path

- Increased Design Freedom with Eurovech

- Can Be Joined to Different Materials

- detail_img

-